It’s found underground, it’s used in a huge variety of human endeavors and, according to Worcester Polytechnic Institute Professor Diran Apelian, it’s in desperate need of conservation efforts.

But it’s not oil. It’s metal. And not just so-called precious metals but everyday materials like aluminum and copper.

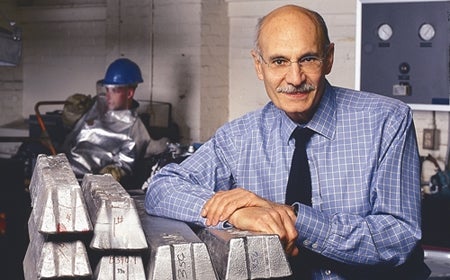

Apelian is heading up a new academic center dedicated to finding new ways, both technical and political, to promote the reuse of metals. Apelian says the Center for Resource Recovery and Recycling will bring together researchers and companies from across the country and even internationally.

In early February, the National Science Foundation gave the center a $400,000, five-year grant to help with its initial efforts.

Right now, Apelian said, a third of the world’s copper is in landfills. When buildings are torn down, he said, unsorted debris, including wires and pipes, is thrown into the waste stream. And the same goes for the gold, cobalt and other metals in computers, cell phones and other gadgets.

“These landfills are going to be like mines for our grandchildren,” Apelian said.

Reuse And Recycling

Starting in April, Apelian said, the center will launch six or seven projects, using students to help with the research. One will focus on improving aluminum recycling with new florescent technology to help sort aluminum scraps based on alloy composition so that they can be melted and recast more easily.

Currently, Apelian said, just 45 percent of aluminum is recycled. And he said sorting and recycling takes just 5 percent of the energy that would be needed to mine and refine new metal.

WPI’s first partner in the center is the Colorado School of Mines. Apelian said the university has experts on metallurgy and extraction techniques that are relevant to, for example, getting tiny pieces of gold out of old cell phones.

Apelian said he’s also in talks with Purdue University in Indiana and Catholic University of Leuven in Belgium about becoming part of the center. He said he’d like to see five or six universities bring their experts together to support the effort.

“In any kind of team… you want to bring the strong partners together so that two plus two is truly six,” he said.

The center also has 12 corporate partners so far and is looking to recruit more. Appelian said the companies will put in $30,000 a year to be part of the center and help direct its research.

“The value proposition’s incredible,” he said. “We’re providing a neutral terrain for all these companies coming together and learning from each other.”

William J. Bernard Jr., president and CEO of Surface Combustion Inc. in Ohio, said his company has had good experience working with WPI in other collaborative efforts before.

“Hopefully this will all lead to more reuse of resources,” he said.

Bernard said companies like his bring their own knowledge of technology and market applications to the center.

Appelian said the center will not focus exclusively on methods of reusing metals but will take on other engineering issues and even policy questions. For example, he said, he hopes it will support design improvements to products like cars and cell phones so their component parts can eventually be dismantled and reused more easily.

Appelian said he’s also concerned about addressing the gap between the price of products and the true social costs involved in obtaining their materials and disposing of them after they break down.

“If you’re not including what it costs to get rid of it to society, you’re just robbing it from the next generation,” he said.