The twin cities area of Fitchburg, Leominster, and surrounding towns in North Central Massachusetts may not be the manufacturing hub it was in the mid-20th century, but for one medical device maker, it’s still an ideal place to call home.

BMP Medical in Sterling, a family-owned business, was poised for long-term success from the start. When Jack Fay founded the company (then Biomedical Polymers) in 1978 in Leominster, he targeted plastic injection molding specifically for medical device manufacturers. That decision buoyed BMP as other plastics companies in the region dwindled when it became cheaper to make plastic parts in other countries.

But in the medical device field, the margin for error is non-existent, and plastic parts used in an array of products in medical laboratories and clinical settings must be validated in a qualified U.S. facility, said John Faulker, the grandson of founder Jack Fay.

“We will partner with many different companies looking to bring a design to life or an existing client they have, helping to mass produce their product,” Faulkner said.

As vice president of sales and marketing, Faulkner grew up knowing one day he’d help lead the private company, which today employs 125. When his grandfather started the business, Faulkner estimated there were roughly 500 injection-molding machines to make plastic products within 10 miles of Leominster. All the supporting shops, like tool makers and packaging facilities, were there, too. Since then, much of that industry has gone overseas.

But Massachusetts is full of life science and biotech companies making products for clinical and laboratory purposes. Some of the big names, such as Millipore Sigma in Burlington, and VWR International in Pennsylvania, contract with BMP to produce their products.

“They need to bridge the gap from product to production,” Faulkner said of his clients. Along with that process comes review, material consultation, sterilization, packaging, and materials consultation inside BMP’s 80,000-square-foot facility in Sterling.

Notably, Waltham-based medical equipment manufacturer Rhinostics worked with BMP Medical in the production of a new type of nasal swab that doesn’t use cotton, which greatly reduced the processing time of COVID-19 tests during the pandemic.

Innovative clients like these make Massachusetts an enduring locale for a company like BMP, Faulkner said.

After rebranding to BMP Medical and relocating the former Gardner headquarters to a larger facility in Sterling in 2018, the company has expanded its capabilities to include all operations, from production in a cleanroom to packaging and assembly. Faulkner said there’s even room to grow.

“We’ve been heavily investing in our company here, and I think that our growth has always been healthy,” Faulkner said.

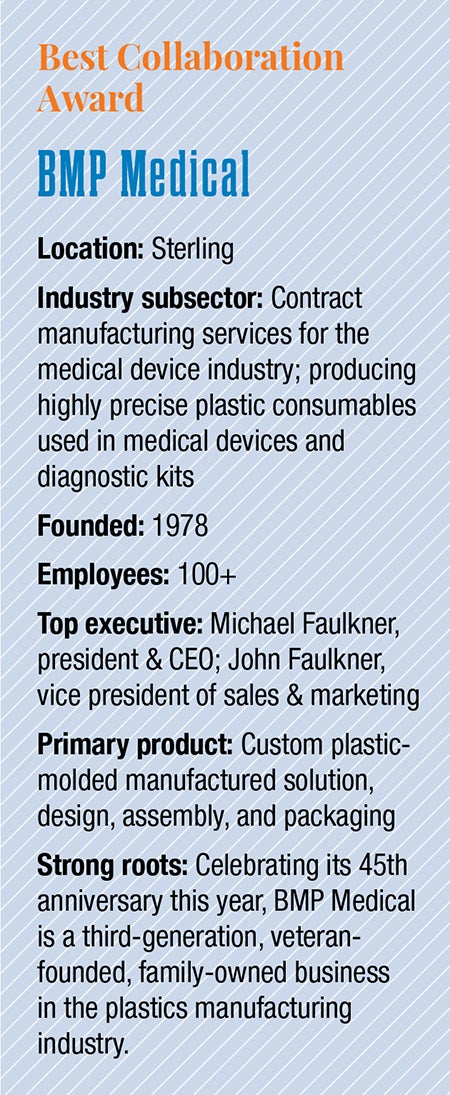

2023 Manufacturing Excellence Awards

- Overall Manufacturing Excellence: Wirefab, Inc.

- Best Collaboration Award: BMP Medical

- Manufacturing Champion: Yan Wang

- Rising Star: Multiscale Systems

- Green Manufacturing Award: VALIS

- Top Product Design & Innovation: FLEXcon Co., Inc.

- Workforce Development Award: Rentschler Biopharma, Inc.