WPI professor and Ascend Elements co-founder to research new battery recycling tech for Boston firm

Photos | Courtesy of Worcester Polytechnic Institute

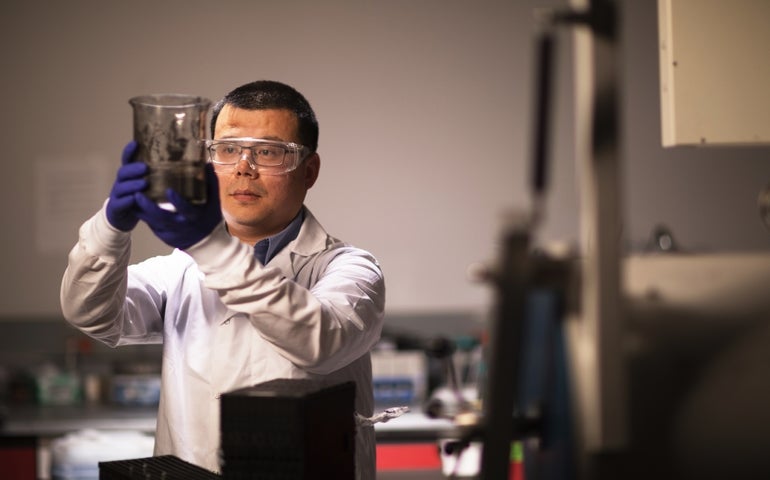

One of the key beliefs of Yan Wang from Worcester Polytechnic Institute is university research must make its way into industry.

Photos | Courtesy of Worcester Polytechnic Institute

One of the key beliefs of Yan Wang from Worcester Polytechnic Institute is university research must make its way into industry.

A first-of-its kind lithium-metal battery recycling process may be on the horizon as SES AI will fund a two-year research initiative at Worcester Polytechnic Institute to develop the new technology.

SES AI, a li-metal battery manufacturer, is a global enterprise with headquarters in Boston, and operations in Singapore, Shanghai, and Seoul. Qichao Hu, founder, chairman, and chief executive officer of SES AI, reached out to WPI’s professor of mechanical and materials engineering, Yan Wang, to lead the research.

Wang’s research at WPI has helped develop materials recycling processes for the EV industry. In 2015, he and a group of cofounders created Ascend Elements, a Westborough-based firm, which has based billions to build EV battery recycling facilities in Kentucky, Poland, and Germany.

“Eventually, my goal is to help the industry,” said Wang. “To lower carbon dioxide emissions, lower the cost … that’s one of my passions as a researcher, as a professor.”

Neither SES AI nor WPI disclosed the amount of funding.

“We are thrilled to collaborate with WPI, Professor Wang, and his team of experts on this initiative to develop a critical new battery recycling technology that will allow SES AI to implement a more sustainable and efficient approach to battery manufacturing,” Hu said in an SES AI press release Friday.

Li-metal is a new technology yet to experience wide-scale commercialization, said Hu. Thus, there isn’t li-metal to be recycled yet, though a time when there needs to be that option is coming soon, he said.

“Because we’re the furthest ahead and because we produce more lithium metal batteries, the recycling of lithium metal becomes important,” Hu said in a phone interview with WBJ.

The impending heightened use of li-metal batteries is a motivating factor for developing a recycling process for Wang as well.

“One thing [that] convinced me to work on the topic is I truly believe that electrification of the industry, that means that there will be lots of parts powered by batteries,” Wang said in an interview with WBJ.

The importance of creating technology enabling li-metal battery recycling is twofold, said Hu. One reason to create the technology is cost. Li-metal is mined in areas such as South America and Australia, then shipped to areas of Asia to be refined before being sent to the United States to be used in production, which is a pricey process, he said.

Traceability is the other incentivizing factor. There’s a lack of transparency when buying fresh li-metal, with companies unable to track the processes used to mine, refine, and transport the product, said Hu.

“If you do recycling, then you have the full history,” he said. “You can trace all that. You know which battery the lithium was used in in its previous life and then where it's recycled, and then which new battery that recycled lithium actually goes into.”

Another benefit to developing recycling technology is cutting down on the environmental harm occurring throughout the transport of li-metal, said Wang. Transportation of li-metal around the globe releases CO₂, contributing to global warming.

Creating a recycling process will allow for the procedure to take place on-site, said Hu. This means that handlers will be able to take the li-metal out of the batteries and put it into new ones, accounting for traceability accuracy, eliminating costly transportation prices, and reducing CO₂ emissions.

WPI will use the majority of the funds provided by SES AI for hiring graduate and postdoctoral students to participate in creating the technology, Wang said. In addition, because li-metal is highly reactive, both Hu and Wang said a portion of the financing will go towards protective precautions to keep students safe.

Though the deployment of a recycling process will initially benefit companies making products that use li-metal batteries, such as electric cars, consumers will eventually reap the benefits as well, said Hu. He predicts lower manufacturing costs will translate to lower prices of consumer goods.

0 Comments